Concrete block making machine

1. The cement brick making machine adopts four-column orientation and is equipped with a strong vibration motor.

2. The machine adopts upper die push and pull, manual scraping, and brick output. The operation is convenient and flexible, and you can quickly become familiar with it.

3. The machine body is made of large steel and special welding technology and materials, which is strong and shockproof.

4. The wooden pallet will not be impacted by the synchronous resonance with the mold during forming, and the service life of the wooden pallet will be more than double that of similar products.

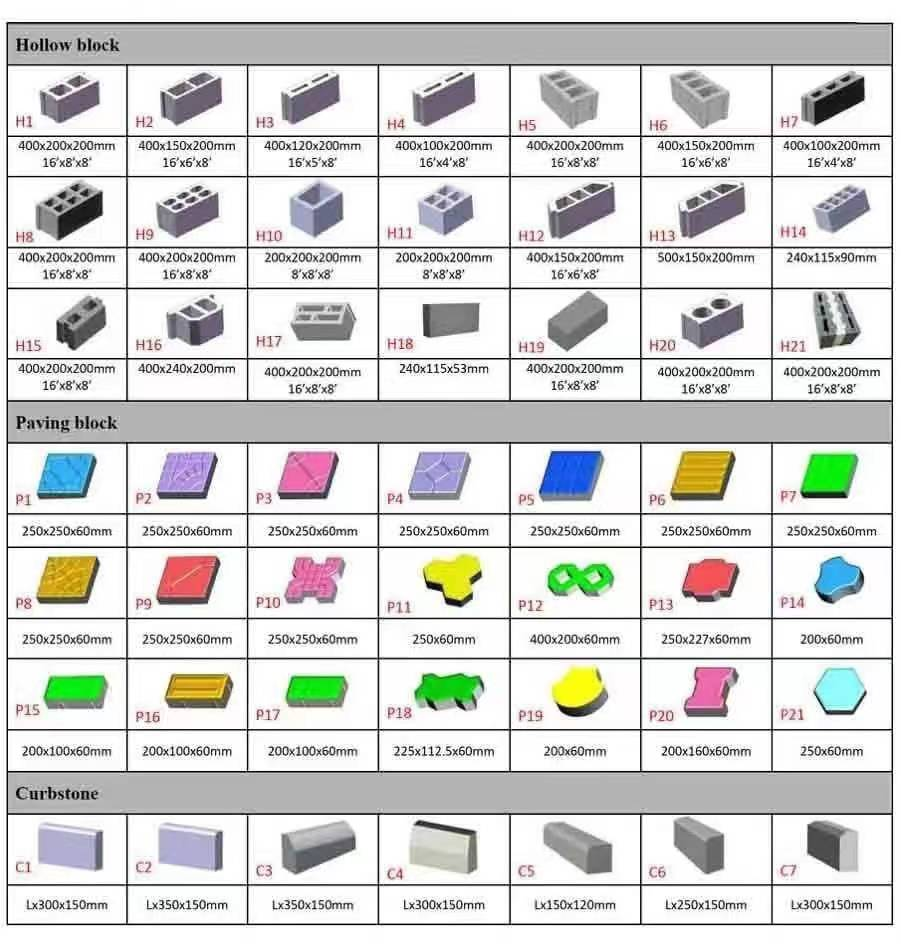

5. One machine with multiple functions, equipped with different specifications of molds, can produce different specifications of cement bricks, and the molds are easy to replace and maintain.

6. The pressure head can move longitudinally, which is convenient for feeding, maintenance and washing. The gap between the pressure foot and the mold box is small, the block burrs are small, and the appearance is good.

Description

Features and configuration:

1. The machine body is all made of strong square steel welding, which is extremely strong and resistant to vibration and stable in operation.

2. The mold box adopts column sliding, compact coordination, synchronous and stable lifting, and the block forming rate is greatly improved.

3. The pressing head can slide and shift, which is convenient for mold box cloth and greatly improves the efficiency.

4. The lifting part of the mold box is installed to prevent the pressing head from damaging the machine during operation.

5. When the vibration is adopted, the vibration is excited at the same time. The four walls of the mold box are equally stressed to achieve the molding effect, ensuring high density of the block, neat and beautiful edges and corners. 6. Equipped with a flat-mouth 350 forced mixer and pusher that are synchronized with the production of this machine.