-

The concrete electric dumper machine be widely used in light weight wall panel products lines,slab floor production,boundary production line,for the concrete transfer from batching plant to the machine,It is an auxiliary machine for the production of lightweight partition panels, and at the same time, it can also be used as a supporting equipment for a concrete precast plant.

The concrete electric dumper machine be widely used in light weight wall panel products lines,slab floor production,boundary production line,for the concrete transfer from batching plant to the machine,It is an auxiliary machine for the production of lightweight partition panels, and at the same time, it can also be used as a supporting equipment for a concrete precast plant. -

1.The Machine work on the principle of pushing extrusion for making the precast concrete pillars, columns or posts . According to the sizes of pillars, the machine can make the 4-8 rows of concrete products . It is very efficient . About 300 meter length of precast concrete pillars can be made per working hour. 2.Various shapes and sizes can be customized according to customer requirements, such as:H, L, T, Square shape.

1.The Machine work on the principle of pushing extrusion for making the precast concrete pillars, columns or posts . According to the sizes of pillars, the machine can make the 4-8 rows of concrete products . It is very efficient . About 300 meter length of precast concrete pillars can be made per working hour. 2.Various shapes and sizes can be customized according to customer requirements, such as:H, L, T, Square shape. -

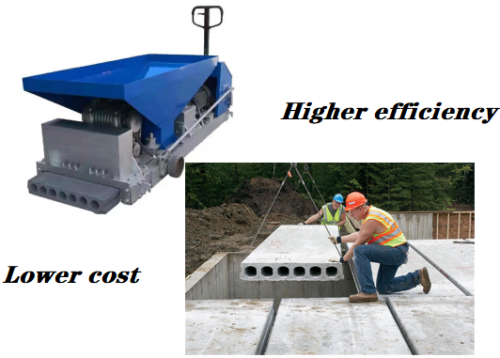

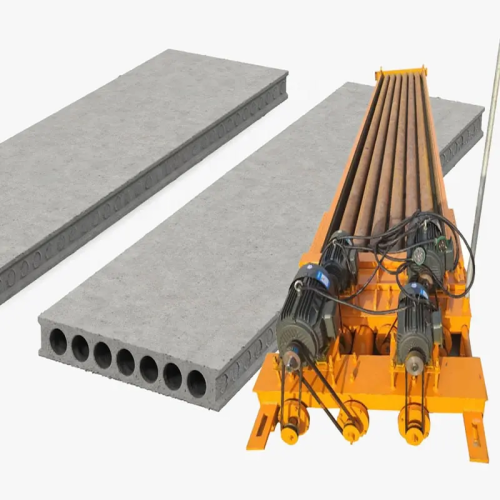

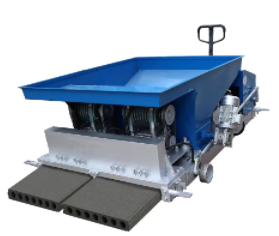

1. The hollow core slab machine meets all the international quality 2. The concrete hollow core slab pushing machine is easy to maintain, and importantly, the production of slab is high-strength concrete structures, good qualitv and smooth surface. 3. The concrete slabs are mainly used as the roofing slab in the buildings. They are stout with many steels inside. 4.We can also design and produce the machines according tocustomers'special demand. Please choose at belowaccordingly

1. The hollow core slab machine meets all the international quality 2. The concrete hollow core slab pushing machine is easy to maintain, and importantly, the production of slab is high-strength concrete structures, good qualitv and smooth surface. 3. The concrete slabs are mainly used as the roofing slab in the buildings. They are stout with many steels inside. 4.We can also design and produce the machines according tocustomers'special demand. Please choose at belowaccordingly -

1. Driven by Several High-frequency vibration rods inside the concrete. so the concrete mixture are high density uniformly when finished! 2. The Machine making prestressed concrete hollow slab that does not require cutting machine. Thus, saving a lot of cutters discs. 3. The device is light weight and easy to transport. 4.In addition to concrete transport need workers, the product molding and de-molding shifts are finished automatically.

1. Driven by Several High-frequency vibration rods inside the concrete. so the concrete mixture are high density uniformly when finished! 2. The Machine making prestressed concrete hollow slab that does not require cutting machine. Thus, saving a lot of cutters discs. 3. The device is light weight and easy to transport. 4.In addition to concrete transport need workers, the product molding and de-molding shifts are finished automatically. -

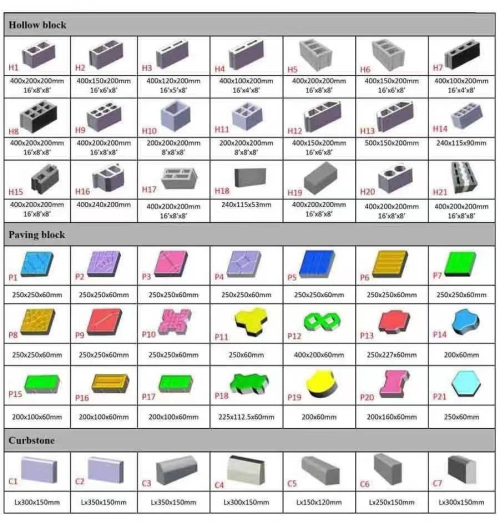

1. The cement brick making machine adopts four-column orientation and is equipped with a strong vibration motor. 2. The machine adopts upper die push and pull, manual scraping, and brick output. The operation is convenient and flexible, and you can quickly become familiar with it. 3. The machine body is made of large steel and special welding technology and materials, which is strong and shockproof. 4. The wooden pallet will not be impacted by the synchronous resonance with the mold during forming, and the service life of the wooden pallet will be more than double that of similar products. 5. One machine with multiple functions, equipped with different specifications of molds, can produce different specifications of cement bricks, and the molds are easy to replace and maintain. 6. The pressure head can move longitudinally, which is convenient for feeding, maintenance and washing. The gap between the pressure foot and the mold box is small, the block burrs are small, and the appearance is good.

1. The cement brick making machine adopts four-column orientation and is equipped with a strong vibration motor. 2. The machine adopts upper die push and pull, manual scraping, and brick output. The operation is convenient and flexible, and you can quickly become familiar with it. 3. The machine body is made of large steel and special welding technology and materials, which is strong and shockproof. 4. The wooden pallet will not be impacted by the synchronous resonance with the mold during forming, and the service life of the wooden pallet will be more than double that of similar products. 5. One machine with multiple functions, equipped with different specifications of molds, can produce different specifications of cement bricks, and the molds are easy to replace and maintain. 6. The pressure head can move longitudinally, which is convenient for feeding, maintenance and washing. The gap between the pressure foot and the mold box is small, the block burrs are small, and the appearance is good. -

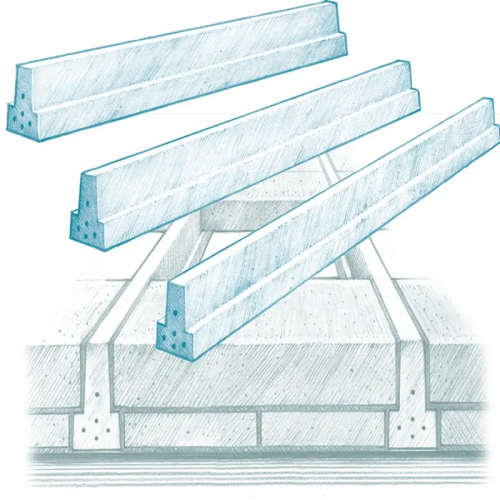

The prestressed concrete t beam machine is one of the new designs for manufacturing prestressed concrete T beams. The machine work on the principle of slipfomer. This gives them an exceptional amount of dimensional stability. Its production efficiency is 4-5 times compared to the traditional molding method. The finished concrete beams cast by the machine are very compact and smooth. Generally, columns are used in conjunction with bricks. According to the different customers' requirements, we can design the machine to make the different sizes of T beams.

The prestressed concrete t beam machine is one of the new designs for manufacturing prestressed concrete T beams. The machine work on the principle of slipfomer. This gives them an exceptional amount of dimensional stability. Its production efficiency is 4-5 times compared to the traditional molding method. The finished concrete beams cast by the machine are very compact and smooth. Generally, columns are used in conjunction with bricks. According to the different customers' requirements, we can design the machine to make the different sizes of T beams. -

The wall panel extruder is a special machine used to manufacture non-load-bearing concrete wall panels. The finished wall panels are mainly for the application of interior walls or exterior walls in the frame structure buildings as well as the boundary wall.Compared to the well-known acotec panels, the wall panels made by our extuder can be reinforced with steel wires. The machine work on the principle of extrusion. The extruder machine moves at a constant speed along a track. It can produce 1.5meters -1.7 meters long wall panel per minute. Its production capacity of each machien is about 450-500 square meters per minutes.

The wall panel extruder is a special machine used to manufacture non-load-bearing concrete wall panels. The finished wall panels are mainly for the application of interior walls or exterior walls in the frame structure buildings as well as the boundary wall.Compared to the well-known acotec panels, the wall panels made by our extuder can be reinforced with steel wires. The machine work on the principle of extrusion. The extruder machine moves at a constant speed along a track. It can produce 1.5meters -1.7 meters long wall panel per minute. Its production capacity of each machien is about 450-500 square meters per minutes. -

The precast concrete fence wall is a new type of wall structure composed of wall panels and H-shaped columns. The production of precast fence walls requires at least two main machines, namely the concrete boundary wall panel machine and the concrete H column machine. We called the two machines as precast concrete fence wall machine or precast boundary wall machine Both machines work on the extrusion or pushing principle.

The precast concrete fence wall is a new type of wall structure composed of wall panels and H-shaped columns. The production of precast fence walls requires at least two main machines, namely the concrete boundary wall panel machine and the concrete H column machine. We called the two machines as precast concrete fence wall machine or precast boundary wall machine Both machines work on the extrusion or pushing principle.